- Home

- Products

- High Pressure Pipe Fittings

- SS 317/317L High Pressure Pipe Fittings

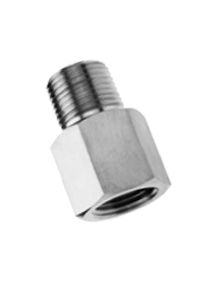

SS 317/317L High Pressure Pipe Fittings

UNS S31700 High Pressure Pipe Fittings Suppliers, Grade 317L Stainless Steel High Pressure Pipe Fittings, Stainless Steel 317/317L High Pressure Pipe Fittings, SS Gr.317 Industrial High Pressure Pipe Fittings, DIN 1.4438 High Pressure Pipe Fittings Manufacturers in Mumbai, India.

With the years of experience in manufacturing, supplying and exporting a supreme quality of Stainless Steel 317 / 317L High-Pressure Pipe Fittings we Virgin Engineers has become a leading and well-known entity in the market. We are fully engaged in manufacturing and supplying all range and variety of products to our patrons both at national and international level. We work with dedicated employees and qualified professionals that adhere to obtain a quality range product. Our vision is to provide quality products and services to our esteem customers. In order to offer them a quality standard product, we acquire the premium quality of raw material that is attained from the reputed dealers of the industry. Along with these, we implement the new and updated technology in our organization for furnishing a dimensional and accurate size product. However, we supply the product in various length, thickness, shape, grade, dimensions and in size as per the mentioned requirements and needs of the patrons.

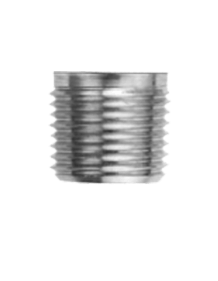

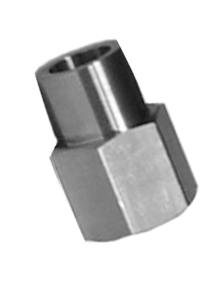

Stainless Steel 317/317L Hex Reducing Nipple, SUS 317 Reducing Bushing, 317L SS Reducing Adapter, SS 317 Hex Long Nipple Exporters, 317L Stainless Steel Hex Coupling Supplier in Mumbai, India.

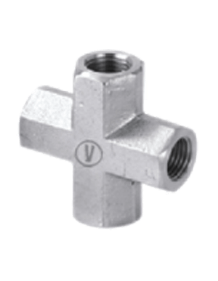

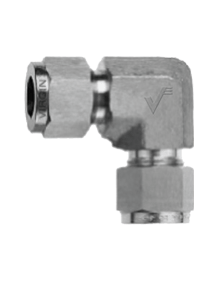

SS 317 Allen SAE Plug, 317L Stainless Steel Gauge Adapter, Austenitic Stainless Steel 317L Union Cross, SS 317L Female Connector, Steel 317L Elbow Reducing Street, AISI 317 Union Elbow, SS 317 Male and Female Elbow.

SS 317 / 317L High-Pressure Pipe Fittings are one of the ranges of austenitic stainless steel alloy that is commonly designated from UNS- S31700/ S31703 pressure pipe fittings. These high-pressure pipe fittings are mainly used in piping systems to attach straight sections of pipes. This high pressure pipe retains high pressures, temperatures and high flow of solutions.

The type 317 grade these are austenitic nickel-chromium stainless steel alloy adding up with molybdenum content that offers superior phenomenal corrosion resistance and higher strength at elevated temperature. These alloys of fittings are exhibited superior resistance to oxidation in intermittent services up to 1600 degree F whereas in continuous services up to 1700 degree F. However these improved the localized and general corrosion and features superior weldability and formability. While on the other hand, the grade 317 L is similar to grade 317, therefore, this alloy of the fitting is the low carbon austenitic stainless steel alloy. The low carbon content offers superior resistance to sensitization during thermal and welding processes. This grade exhibits superior resistance to corrosion over a wide range of chemicals, especially in acidic chlorides environments.

Both the grades of pipe fittings assures outstanding resistant to general and chloride pitting corrosion. Furthermore, it offers excellent creep, tensile and stress to rupture strength at elevated temperatures as compared to other grades. The common hot working process is done at range of 2100 -2300 degree F whereas cold working is successfully performed through stamping, heading and shearing. Therefore these alloys of pipe fittings are not heat treated thus the cold working process possess superior strength and hardness.

Testing of product

To offer superior quality and zero defect product to the

customers we test and check the product on various stage of

production at our premises on behalf of our quality auditors.

These tests are like chemical analysis, tensile strength,

flaring test, macro/micro test, mechanical test, ultrasonic

test, PMI test, and flattening test. Furthermore, the test is

the IGC test, pitting resistance test, radiography test, and

hardness test.

Packing details

To make a safe delivery of products these are packed in wooden

pallets, wooden cases and in boxes.

Specification

Types

High Pressure Pipe Fittings

End Connections :

NPT, BSP, & BSPT.

Size Range

1/16” to 2”

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

| C | Mn | Si | P | S | Cr | Mo | Ni | Fe | |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Close Nipple

Hex Nipple

Hex Reducing Nipple

Hex Long Nipple

Reducing Adapter

Reducing Bushing

Hex Coupling

Hex Reducing Coupling

Elbow Female

Elbow Reducing Street

Male Elbow

45° Elbow Female

45° Elbow Street

Tee Female

Tee Street

Tee Branch

Tee Male

Cross Female

Union Ball Joint

Hex Female Cap

Hex Male Plug

Allen Plug

Hex SAE Plug

Allen SAE Plug

SAE Adapter

Hex Pipe Plug

Gauge Adapter

Male Connector

Female Elbow

Union Cross

Female Connector – FF

Union

Union Elbow

Male Adaptor NPT

BSPT Coupling

Quality Assurance

Stainless Steel S31700/S31703 High Pressure Pipe Fittings are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 317/317L High Pressure Pipe Fittings are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

stainless steel 317 male elbow dealers, buy high quality austenitic stainless steel 317l hex female cap, stainless steel 317l 45° elbow female manufacturer in mumbai, ss 317 hex nipple, 317 ss gauge adapter size, ss 317 hex coupling, 317 ss hex male plug and sae plug, stainless steel 317 reducing bushing types, stainless steel 317l close nipple, steel 317 male connector specification, 317l ss adapter & reducing adapter size, ss 317 elbow street price, ss 317l 45° elbow street india, ss 317 hex reducing coupling size, 317l ss sae adapter, ss 317l high pressure pipe fittings chemical composition, stainless steel 317/317l high pressure pipe fittings standards, stainless steel 317 hex reducing nipple, ss 317/317l high pressure pipe fittings stockholder, ss 317/317l high pressure pipe fittings traders, stainless steel 317 elbow female, steel 317l allen plug, stainless steel 317l hex pipe plug mechanical priperties, stainless steel hex long nipple grade 317, ss 317 elbow reducing street stockists, 317l ss cross female, stainless steel 317l tee female/street/branch/male distributors.

© Copyright | Virgin Engineers 2021. All Right Reserved.