- Home

- Products

- Pipes / Tubes

- SS 347 / 347H Pipes and Tubes

SS 347 / 347H Pipes and Tubes

Stainless Steel 347H Tubing, Stainless Steel 347 Tube, UNS S34700 Pipes and Tubes, DIN 1.4550 Pipes and Tubes, SS 347H Pipes, UNS S34709 Pipes and Tubes, Stainless Steel 347 Pipes, ASTM A213 SS 347H Tube Suppliers, Grade 347H Stainless Steel Seamless Pipes, ASTM A269 SS 347 Welded Tube Manufacturers in Mumbai, India.

At Virgin Engineers, we are committed to manufacturing and supplying top-grade stainless steel 347 pipes and tubes designed for critical industrial requirements. Columbium (niobium) helps these stainless steel grades resist damage from corrosion between the grains, especially after welding. We produce these pipes and tubes in a wide range of sizes, finishes, and thicknesses to cater to industries with elevated temperature and corrosive media challenges.

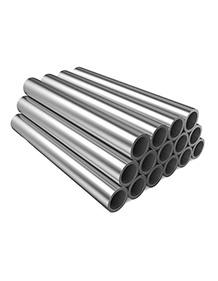

Our Stainless Steel 347H pipes and tubes are available in seamless, welded, ERW, and EFW variants. Sizes range from 1/8” NB to 36” NB, with wall thickness options covering SCH 5 to SCH XXS, and we also support customized dimensional specifications. All products are manufactured in compliance with global standards, such as ASTM A312, A213, A269, and ASME SA312, SA213, and SA269, with precision in dimensional tolerances, finish, and mechanical strength. Ends are supplied as plain, beveled, or threaded, depending on the client's requirement.

DIN 1.4961 Pipes and Tubes, SS 347 Seamless Tube, ASME SA358 SS 347H EFW Pipes, SS 347H Piping Exporters in India, Stainless Steel 347 Welded Pipes, SS 347 ERW Tubes, SS 347 Pipe and Tube Supplier in Mumbai, India.

SS 347 Round Pipes, SS 347 Threaded Pipes and Tubes Stockist, SUS 347 Polished Pipes & Tubes, ASTM A312 SS 347H Seamless Pipes Exporters, Grade 347H SS Coiled Tubing, SS 347H Square Tubes.

Niobium treatment helps the SS 347 grade resist issues such as carbide precipitation and stress-induced corrosion. It is ideal for use in welded constructions. SS 347H, the high-carbon version, offers improved creep strength and is better suited for high-temperature service. At Virgin Engineers, we manufacture and test every product batch with strict metallurgical standards to ensure performance under pressure and thermal stress. Each 347 pipe and tube is marked with a heat number and grade details for traceability.

With a reliable production process and quality-focused workforce, we maintain consistent stock availability of SS 347 and 347H pipes and tubes in both domestic and export packaging. Our infrastructure is capable of handling bulk orders while ensuring timely deliveries. All products undergo dimensional inspection and mechanical tests to ensure conformance with customer specifications and industry benchmarks.

Testing the Product:

- Positive Material Identification (PMI): Confirms grade and alloy composition before dispatch.

- Hydrostatic Pressure Test: Ensures strength and leak-free performance under internal pressure.

- Ultrasonic Testing: Detects internal imperfections or discontinuities in the pipe.

- Mechanical & Tensile Testing: Measures elongation, yield, and tensile strength properties.

- Dimensional and Visual Inspection: Ensures tolerance, straightness, and surface finish are as per standards.

Documentation:

- Mill Test Certificates (EN 10204 3.1): Provided for each batch with chemical and mechanical properties.

- Third-Party Inspection Reports (TPIs): Available on request from approved agencies.

- Raw Material Traceability Reports: Documenting the material origin and batch tracking.

- Heat Treatment Records: Certifying the thermal processing stages as per standard.

- Compliance Certificates: Available for NACE, IBR, PED, and other project-based requirements.

Packaging of Product:

- Strapped in bundles with protective wrapping: For safe transportation and handling.

- Export-quality wooden crates or pallets: This guarantees a delivery without any damage to clients abroad.

- End caps on pipes: Prevent dirt, moisture, and impact during shipping.

- Waterproof wrapping: Protects against environmental moisture during transit.

- Customized packaging options: Provided as per client's logistics and project needs.

Quality Assurance:

- Conforms to ASTM, ASME, and international standards: This ensures global reliability and performance.

- Batch-wise inspection and full traceability: Maintained through documented control procedures.

- The in-house quality control (QC) system, which includes a third-party option, provides a dual assurance system designed to meet buyer requirements.

- Certified ISO 9001 Quality System: Backed by quality manuals, SOPs, and inspection plans.

Material Testing:

- Spectro Analysis for Chemical Composition: Confirms alloying elements in each batch.

- IGC (Intergranular Corrosion) Testing: Checks weld-area corrosion resistance.

- Hardness Test: Assesses surface and core hardness.

- Flaring & Flattening Tests: Evaluates the pipe's mechanical deformation limits.

- Microstructure Examination: Ensures consistent grain flow and freedom from segregation.

Specification

ASTM

ASTM A312, A213, A269, A358, A249, DIN, ASTM, BS and all International Standards.

Type

Seamless, ERW, Welded, Fabricated, LSAW.

Thickness

0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm

Pipe Size / Tube Size

1/2" to 16"NB / 1/8" to 30"NB

ERW / EFW Pipe Size

1/2" to 24"NB / 6"NB to 100"NB

Other

Length - Single Random, Double Random and Cut Lenght.

End - Plain End, Beveled End, Threaded etc.

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | X6CrNiTi18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | X12CrNiTi18-9 |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 347 | 0.08 max | 2 max | 1 max | 0.045 max | 0.030 max | 17 - 19 | 0.10 max | 9 - 12 | 5(C+N) – 0.70 max |

| SS 347H | 0.04 – 0.10 | 2 max | 1 max | 0.045 max | 0.030 max | 17 - 19 | 0.10 max | 9 - 12 | 4(C+N) – 0.70 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Seamless Pipes

Welded Pipes

Seamless Tubes

Welded Tubes

EFW Pipes

EFW Tubes

ERW Pipes

ERW Tubes

Round Pipes & Tubes

Square Pipes & Tubes

Rectangular Pipes & Tubes

Threaded Pipes & Tubes

Popular Searches

347 stainless steel tubing sizes, prime quality tp347h stainless steel seamless pipes, a312 tp347 stainless pipe, tp347h seamless stainless steel pipes, stainless steel 347h schedule 40 pipe, schedule 40 stainless steel 347h pipe, tp347h seamless pipes for high pressure, stainless steel 347 pipe price, ss 347h seamless pipe sizes, stainless steel 347 tubing suppliers in mumbai india, stainless steel 347 mechanical tubing, stainless steel tp 347h sanitary tubing, astm a213 tp347 price in india, 347h stainless steel pipe specifications, 347 stainless steel tubing price in mumbai india, stainless steel 347h pressure pipe, ss 347 pipe schedule chart, 347 stainless steel pipe price list, schedule 10 stainless steel 347 pipe, stainless steel 347h coil tube, a312 tp347 welded stainless steel, polished stainless 347 tubing, jindal ss 347 pipes price list, 347 stainless coil tubing, a312 tp347h seamless pipes, tp347 seamless pipe manufacturer, a312 TP 347 precision stainless steel tubing suppliers, india, erw stainless steel 347h pipe, large diameter steel pipe manufacturers in india, stainless steel tube manufacturers in mumbai, 347 stainless steel tubing suppliers.

© Copyright | Virgin Engineers 2021. All Right Reserved.