- Home

- Products

- Needle & Gauge Valves

- Incoloy Alloy 800 / 800H / 800HT Needle & Gauge Valves

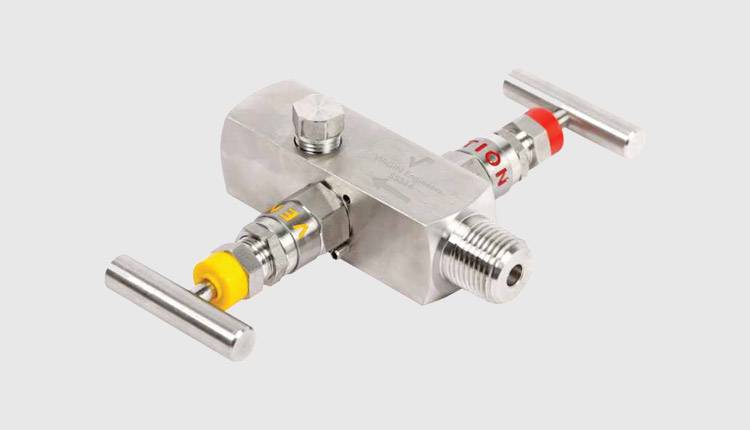

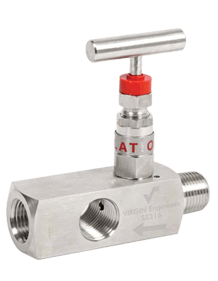

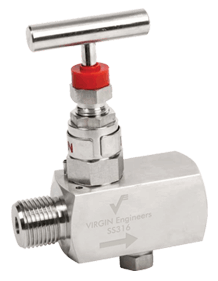

Incoloy 800 / 800H / 800HT Needle & Gauge Valves

Incoloy 800 Needle and Gauge Valves, Incoloy 800H Needle & Gauge Valve, Incoloy 800HT Needle & Gauge Valve Suppliers, UNS N08800 Needle & Gauge Valves, DIN 1.4876 Gauge Bleed Needle Valves, Incoloy® Alloy 800 Industrial Needle & Gauge Valve Manufacturers in Mumbai, India.

Virgin engineers are highly acclaimed industry that is fully busy in manufacturing the commendable quality of Incoloy Alloy 800/800H/800HT Needles & Gauge Valves. We are providing the wider ranges of needle valves so that all applications demands in diverse industries get easily fulfilled. We are offering the same to the buyers at national and international product quality standards to our global and domestic buyers. These are today used extensively in many industrial applications. The industry dealing worldwide as a reliable manufacturer and supplier are providing it at standard specifications that vary in design, standards, dimensions, end connections, temperature rating, working pressure, and types.

Incoloy 1.4958 Gauge Vent Valves Exporters, Incoloy 800 Parker Needle Valve, Incoloy® 800H Multiport Gauge Valves Supplier in Mumbai, DIN 1.4859 Screwed End Needle Valve, Incoloy N08811 Hydraulic Needle Valve, India.

Incoloy Alloy 800HT Autoclave Needle Valve, UNS N08810 Needle and Gauge Valves, Alloy 800HT Gauge Valve, Incoloy 800 Needle Valve, Incoloy® Alloy 800H Integral Bonnet Needle Valve, Incoloy 800 Forged Body Gauge Valve.

Qualities of the product-

- Many qualities are found in the product due to which it has become an ideal choice particularly for various critical industrial applications. High tensile strength, good dimensional accuracy, fine surface finishes, corrosion resistant, flexible to use, toughness, anti-corrosive body, withstand high temperature, etc are properties responsible in making it be a perfect choice.

The manufacturing process-

The manufacturing of Incoloy 800 800H 800HT Needles & Gauge Valves begins up with the use of very good quality of raw materials under the guidance of professional experts. The team of experts is guiding the workers at all level of production so that the excellent quality of product fabrication is guaranteed. In order to fabricate the superior quality of needles valves, the proper utilization of sophisticated technology and the newest tools/machinery is recommended. The product ranges offered to the buyers are engineered by keeping in mind raw material quality standards and production norms.

Testing of the product-

The testing of produced product is well conducted by the industry with the clear aim of checking how good the product quality is. The test conducted is namely hardness test, pitting resistance test, chemical analysis, mechanical test, intergranular corrosion test, and positive material identification test. as per the end applications other destructive and non-destructive tests are performed.

Inspection-

The industry is welcoming inspection at their manufacturing unit with the well-defined objective of assuring the effectiveness of the production process of needle valves. The inspection begins from the first stage that is checking the quality of procured raw material to the last stage that is of product packaging and dispatching. The inspection is conducted by the skilled, trained, experienced and legally certified third party inspection agency.

Test certificate-

We are providing essential test certificate to the buyers like MTC as per EN 10204/3.1B, buyers report, third-party test report and 100% radiography test report.

Documenting-

To the buyers, several documents are offered that assures quality and reliability of the product. Heat treatment chart, quality assurance plan, raw material test report, material traceability report, NABL approved lab test report, certificate of origin, fumigation certificate are few documents offered to the buyers

Product packaging-

at the time of shipping of Incoloy 800 /800H /800HT Needles & Gauge Valves proper packaging is recommended for safer transiting. The packaging of the product is done in polyethylene bags and in cardboard boxes and that leads to have damage free delivering.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design :

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Incoloy 800 | N08800 | 1.4876 | Z8NC32-21 | X10NiCrAlTi32-20 | NCF 800 | NA 15 | ЭИ670 | XH32T |

| Incoloy 800H | N08810 | 1.4958 / 1.4876 | Z8NC33-21 | X5NiCrAlTi31-20 | NCF 800H | NA 15(H) | ЭИ670 | XH32T |

| Incoloy 800HT | N08811 | 1.4859 / 1.4876 | - | X8NiCrAlTi32-21 | NCF 800HT | NA 15(HT) | ЭИ670 | XH32T |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Ai | Ti |

| Incoloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000, MPa – 520 | Psi – 30,000, MPa – 205 | 30 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Incoloy N08800, N08810, N08811 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Incoloy 800 / 800H / 800HT Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

incoloy 800 needle valve distributors, 800ht incoloy alloy gauge valve, buy high quality incoloy® 800ht needle and gauge valve, incoloy® 800 parker needle valve india, incoloy 800 screwed end needle valve stockists, alloy 800ht forged body gauge valve types, incoloy 800 gauge & needle valve stockholder, incoloy 800h gauge valve, incoloy alloy 800ht gauge/needle valve traders. incoloy 800ht hydraulic needle valve, incoloy alloy 800h integral bonnet needle valve price, incoloy 800h gauge vent valves, incoloy alloy 800 block & bleed gauge valves, 800ht incoloy alloy high pressure gauge valve size, incoloy alloy multiport gauge valves grade 800, incoloy 800ht 3 way needle valve dealers, incoloy® 800 bonnet needle valves size, incoloy 800ht needle & gauge valve standards, incoloy alloy 800h needle shutoff and regulating valves standards, incoloy® alloy 800ht gauge bleed needle valves, incoloy alloy 800h autoclave needle valve manufacturer in mumbai.

© Copyright | Virgin Engineers 2021. All Right Reserved.