- Home

- Products

- Needle & Gauge Valves

- Inconel 601 Needle & Gauge Valves

Inconel 601 Needle & Gauge Valves

Inconel® Alloy 600 Needle & Gauge Valve Suppliers, Grade 600 Inconel Gauge Valves, UNS N06601 Needle & Gauge Valve, DIN 2.4851 Needle & Gauge Valve, Alloy 600 Inconel Industrial Needle & Gauge Valve, Inconel 600 Gauge Bleed Needle Valves Manufacturers in Mumbai, India.

Inconel 601 which is a nickel chromium alloy is widely used in the industrial applications where there is a high resistance to corrosion and extreme temperature resistance. The alloy was specifically designed in order to offer its services in cryogenic and high elevated temperatures. The alloy grade is usually non magnetic in nature which also offers high strength, and excellent weldability under a severe environment. Also, the high nickel content present in the grade offers improved resistance properties even in the reduced conditions which ultimately makes it highly resistive to corrosive environment. The other good properties found in the grade include pitting resistance to chloride ion solutions, and ultimate resistance to alkaline solutions.

The alloy also exhibits some of the great mechanical properties which include high yield and tensile strength, great creep rupture properties and extensive elongation. Hence, the Inconel 601 Needle & Gauge Valves can be used in various industries across the world.

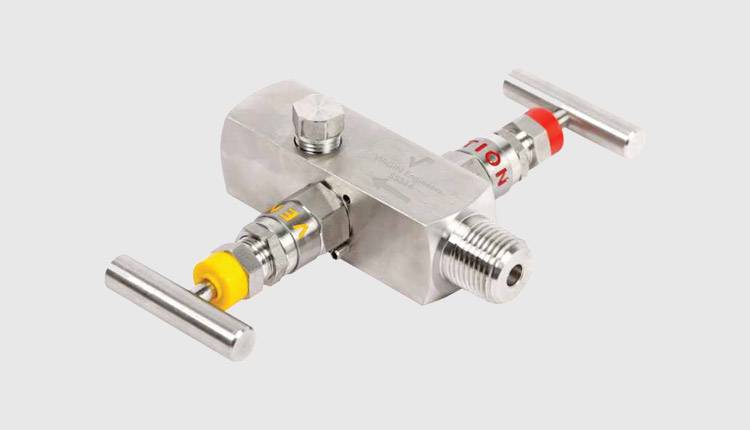

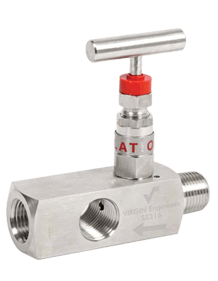

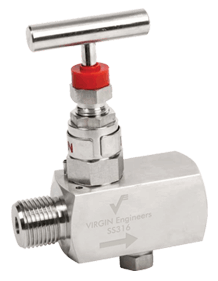

Inconel 601 Screwed End Needle Valve, Inconel 601 Hydraulic Needle Valve, Inconel 601 Parker Needle Valve, Inconel Alloy 601 Gauge Vent Valves Exporters, Inconel® 601 Multiport Gauge Valves Supplier in Mumbai, India.

Inconel Alloy 601 Gauge Valve, Inconel 601 Needle Valve, Inconel 601 Needle / Gauge Valves, Inconel 601 Forged Body Gauge Valve, Inconel® Alloy 601 Integral Bonnet Needle Valve, Inconel 601 Autoclave Needle Valve Needle and Gauge Valves.

A brief info of the services offered by the manufacturer:

Virgin Engineers, one of the leading names in the market are engaged in offering high quality of Inconel Alloys 601 Needle & Gauge Valves to their customers across the world. We are the prominent manufacturer, exporter and supplier of top notch quality of valves. Other features include high end finishing, accurate dimensions, and great performance are some of the traits. Other than this, the valves can be ordered in customized manner varying in size, shapes and thickness as per the necessity of the buyers. In order to maintain the quality of the product we use finest modern tools and inventories in the fabrication process.

Our highly trained professionals are engaged in checking the quality of the valves at every stage of its manufacturing. Furthermore, the packaging done by us is done in fumigation free wooden boxes, crates and cases in order to ensure its quality. We provide relevant shipping documents along with the product to their buyers.

At Virgin Engineers, we are engaged in offering high quality of valves to their customers. Hence, we conduct relevant material quality tests which tell more about the product. Tests such as mechanical tests, pitting resistance tests, positive material tests, intergranular corrosion tests, flaring and flattening tests, bend tests and micro and macro tests are some of the tests performed.

Talking about the documentations, we offer relevant documentations to our buyers so that they can easily counterpart the product with the offered documents. Testaments such as welding procedure specification, QAP, heat treatment chart. Other documents are packaging list that includes the net and the gross weight, fumigation certificate, material tests certificate and material traceability record are some of the documents offered.

Besides, we also offer tests certifications along with the Alloys 601 Needle & Gauge Valves to our buyers across the world. All of these certifications help the buyers to ensure about the delivered product and get to know all sort of information. Tests certificates such as MTC report in conformance

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design :

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 601 | N06601 | 2.4851 | NC23FeA | NiCr23Fe | NCF 601 | NA 49 | XH60BT | - |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.00 max | 0.50 max | 0.015 max | 1.00 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000, MPa – 550 | Psi – 30,000, MPa – 205 | 30 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Inconel N06601 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel 601 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel® 601 parker needle valve india, multiport gauge valves inconel alloy grade 601, inconel 601 block & bleed gauge valves, inconel 601 3 way needle valve dealers, inconel 601 gauge valve, inconel alloy 601 high pressure gauge valve size, inconel 601 integral bonnet needle valve price, inconel® 601 bonnet needle valves size, buy high quality inconel® 601 needle and gauge valve, inconel 601 screwed end needle valve stockists, inconel 601 needle & gauge valve standards, inconel® alloy 601 gauge bleed needle valves, inconel alloy 601 gauge/needle valve traders, inconel 601 hydraulic needle valve, 601 inconel alloy gauge valve, inconel alloy 601 needle shutoff and regulating valves standards, inconel 601 gauge vent valves, alloy 601 forged body gauge valve types, inconel 601 gauge & needle valve stockholder, inconel alloy 601 autoclave needle valve manufacturer in mumbai, needle & gauge valve inconel 601 distributors.

© Copyright | Virgin Engineers 2021. All Right Reserved.