- Home

- Products

- Needle & Gauge Valves

- Inconel 600 Needle & Gauge Valves

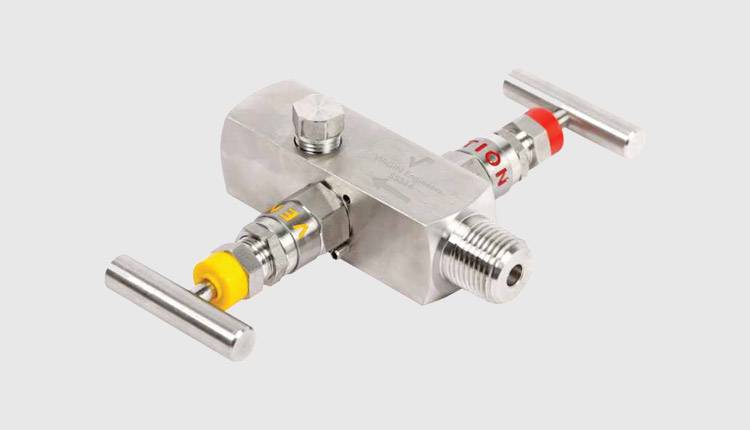

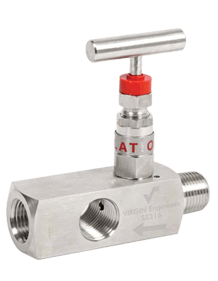

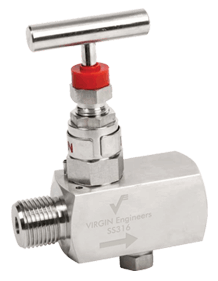

Inconel 600 Needle & Gauge Valves

Inconel Alloy 600 Needle & Gauge Valves, Grade 600 Inconel Gauge Valves, Alloy Gr.600 Industrial Needle & Gauge Valve, Inconel 600 Gauge Bleed Needle Valves Suppliers, Inconel Alloy 600 Needle and Gauge Valves Manufacturers in Mumbai, India.

At Virgin Engineers, we have a decade-long history of pioneering innovation in the industry. We have started our journey with standard machines and fewer working staff, and now we are one of the leading manufacturers, distributors, and suppliers of all types of ferrous and non-ferrous alloys. As such, we implement trending machinery and equipment to draw products per customers' application compatibility. We also deal in the Inconel 600 alloy to make the most prominent Inconel 600 Needle & Gauge Valves. These are well known for their service to any application type. Daily, our workforce is gaining experience in the manufacturing field and making products that meet and exceed the global industrial norms. With a large and technically equipped manufacturing facility, we offer products in various designations, shapes, dimensions, sizes, specifications, and custom dimensions. We are also geared to customers' requirements and products in altered dimensions.

Inconel 600 Hydraulic Needle Valve, Inconel Alloy 600 Gauge Vent Valves Exporters, Alloy Grade 600 Screwed End Needle Valve, JIS NCF 600 Parker Needle Valve, 600 Inconel® Multiport Gauge Valves Supplier in Mumbai, India.

Grade details

It is a standard alloy that requires higher corrosion resistance and abrasion resistance. The Inconel 600 has excellent physical and mechanical constants and also has desired workability and durability. Higher nickel content makes it withstand many organic and inorganic compounds containing environments. It is immune to work in chloride ion and stress corrosion cracking (SCC).

It has a chromium content that improves resistance to oxidizing and reducing environments. Inconel 600 is not a precipitation hardenable. However, the cold-working operation hardens and acquires elevated strength.

Why is Needle & Gauge Valve quality important?

Quality is one of the major aspects of Virgin Engineers. The founders built the policy of quality first. Being an ISO-certified company, we comply with strict quality norms. Our quality measures maintain the stringent quality norms that offer the highest level of quality. This actively contributes towards establishing and acquiring the quality objectives of customers.

It is only possible with tests to run in our testing facility:

- Burst and fire safety tests

- Functional tests (relief test, transfer valve test)

- Valve seat leakage test

- Backseat test

- Closure test

- Hydrostatic tests

Other special tests are shell leakage test, pneumatic test, Cryogenic testing, low-temperature testing, high-temperature, drill stem test, traveling valve test (TV) test, and IGC test.

We ensure only high-class raw materials are present in our production line. We are providing material test certificates as per EN 10204 3.1 or 3.2. Product invoice, specification guide, welding guide, disinfection certificates, national board approval lab (NBAL) test report, packaging details, and attested certificates by us. Other credential reports are raw material test reports, mill test reports, QAP, heat treatment charts, stamping details, and custom reports.

How Inconel 600 Needle & Gauge Valves are packed?

Packed and delivered in standard packaging to avoid damage while exporting to overseas customers. Wooden boxes, cases, plywood cartons, and pallets with plastic film wrapping are mainly used for packaging. Customers can get Inconel 600 Needle & Gauge Valves in different forms, shapes and specifications.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design :

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel Alloy 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Inconel N06600 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel 600 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel 600 needle & gauge valve standards, inconel alloy 600 needle shutoff and regulating valves standards, inconel 600 gauge valve, inconel® alloy 600 gauge bleed needle valves, inconel 600 gauge vent valves, inconel alloy multiport gauge valves grade 600, 600 inconel alloy high pressure gauge valve size, alloy 600 forged body gauge valve types, inconel alloy 600 block & bleed gauge valves, inconel® 600 bonnet needle valves size, inconel 600 hydraulic needle valve, inconel alloy 600 integral bonnet needle valve price, inconel 600 screwed end needle valve stockists, inconel 600 3 way needle valve dealers, inconel alloy 600 autoclave needle valve manufacturer in mumbai, inconel® 600 parker needle valve india, inconel 600 needle valve distributors, 600 inconel alloy gauge valve, inconel 600 gauge & needle valve stockholder, buy high quality inconel® 600 needle and gauge valve, inconel alloy 600 gauge/needle valve traders.

© Copyright | Virgin Engineers 2021. All Right Reserved.