- Home

- Products

- Needle & Gauge Valves

- Incoloy 825 Needle & Gauge Valves

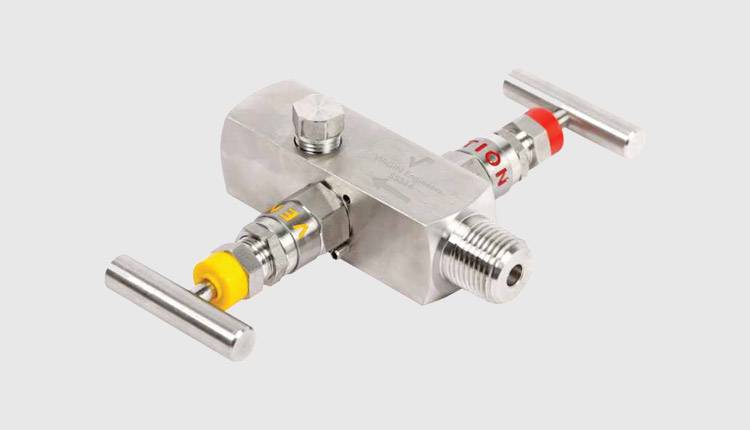

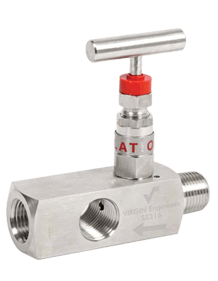

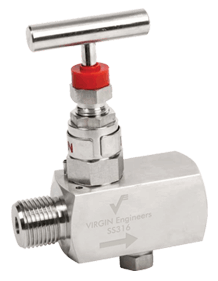

Incoloy 825 Needle & Gauge Valves

Incoloy Alloy 825 Needle and Gauge Valves, Grade 825 Incoloy Gauge Valves, UNS N08825 Needle & Gauge Valves, DIN 2.4858 Needle & Gauge Valves, Incoloy 825 Gauge Bleed Needle Valves Suppliers, Alloy 825 Industrial Needle & Gauge Valve Manufacturers in Mumbai, India.

Virgin engineers are delivering the commendable quality of Incoloy 825 Needle & gauge valves to the domestic and global buyers. The product that they are providing is assuring outstanding usability and also money value. The dealers are dealing at a larger extent globally with the very large numbers of buyers and taking orders in bulk and effectively fulfilling all the demands of the respective buyers. They are leading on the top for being the best manufacturer, supplier, stockholder and exporter of the ranges of needle and valves. It is provided in both standard specifications and custom made specifications. To the buyers, the same is supplied at market leading rates along with sales after/before services.

Incoloy 2.4858 Screwed End Needle Valve, Incoloy 825 Hydraulic Needle Valve, Incoloy 825 Parker Needle Valve, Incoloy Alloy N08825 Gauge Vent Valves Exporters, 825 Incoloy Multiport Gauge Valves Supplier in Mumbai, India.

Incoloy 825 Union Elbow, Incoloy® 825 Union Cross, Incoloy Alloy 825 Allen SAE Plug, Alloy 825 Male and Female Elbow, Incoloy 825 Gauge Adapter, Incoloy 825 Female Connector, Incoloy 825 Elbow Reducing Street.

Alloy details-

Incoloy 825 alloy is chromium, nickel, and iron-based alloy along with the addition of other alloying elements like titanium, copper, and molybdenum. The chemical composition of this alloy is designed in order to provide very good resistance to several corrosive atmospheres. This alloy is similar to the other alloy but it having very well enhanced resistance to the aqueous corrosion. It is also having very good resistant to reducing and also oxidizing acids, pitting, stress corrosion cracking and crevice corrosion. This alloy is resistant to sulfuric acid and phosphoric acid. It is thus used at many industrial applications globally.

Properties of the product-

The product possesses many good attributes to offer because of which it has got greater appreciation in the global market. Those are like anti-corrosiveness, greater usability, high tensile strength, high yielding strength, and good mechanical properties at different as well as at room temperature. Moreover, the product is having resistant ability against pitting, oxidation, crevice corrosion, stress corrosion cracking, carburization, and general corrosion.

Production of the needle and gauge valves-

The manufacturing of Incoloy 825 Needle & gauge valves is executed by using the superior quality of raw materials. Also at the time of product fabrication, the use of modern tools and advanced technology is used so that high quality of product creation is assured. The product is designed by keeping in mind raw material quality standards and manufacturing norms under the guidance of professional experts.

Product test certifications offered-

Product test certifications offered-

The test certifications provided to the buyers are including mill test certifications as per EN 10204/3.1B, third-party inspection report, buyers report, raw material certification, 100% radiography test report.

Documenting of the product-

There are many documents offered to the buyers when the Incoloy 825 Needle & gauge valves are supplied to them. Heat treatment chart, quality assurance plan, commercial invoice, NABL approved lab test report, fumigation certificate, raw material test report, material traceability report, etc are documents offered.

Inspection-

There at the manufacturing unit, the inspection is essentially conducted in order to check the production process. The inspection is executed by the third party inspection agency that is certified legally and is having proper knowledge of inspection based on set parameters.

Packaging-

To supply Incoloy 825 Needle & gauge valves without ruining the quality and causing damages, the packaging is done in wooden cases, carton boxes and wrapped using polypropylene sheets.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design :

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Incoloy 825 | N08825 | 2.4858 | NFE30C20DUM | NiCr21Mo | NCF 825 | NA 16 | ЭП703 | XH38BT |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Ai | Ti |

| Incoloy 825 | 0.05 max | 1.00 max | 0.5 max | 0.03 max | 1.50 – 3.00 | 22.00 min | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000, MPa – 550 | Psi – 32,000, MPa – 220 | 30 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Incoloy N08825 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Incoloy 825 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

incoloy alloy 825 autoclave needle valve manufacturer in mumbai, 825 incoloy alloy gauge valve, incoloy 825 gauge vent valves, incoloy® 825 bonnet needle valves size, incoloy alloy 825 integral bonnet needle valve price, 825 incoloy alloy high pressure gauge valve size, incoloy 825 gauge valve, incoloy® alloy 825 gauge bleed needle valves, buy high quality incoloy® 825 needle and gauge valve, incoloy 825 screwed end needle valve stockists, incoloy 825 3 way needle valve dealers, incoloy alloy 825 gauge / needle valve traders. incoloy 825 hydraulic needle valve, inconel 825 needle valve distributors, alloy 825 forged body gauge valve types, incoloy alloy 825 needle shutoff and regulating valves standards, incoloy alloy 825 block & bleed gauge valves, incoloy alloy multiport gauge valves grade 825, incoloy® 825 parker needle valve india, incoloy 825 gauge & needle valve stockholder, incoloy 825 needle & gauge valve standards.

© Copyright | Virgin Engineers 2021. All Right Reserved.