- Home

- Products

- Needle & Gauge Valves

- Inconel 625 Needle & Gauge Valves

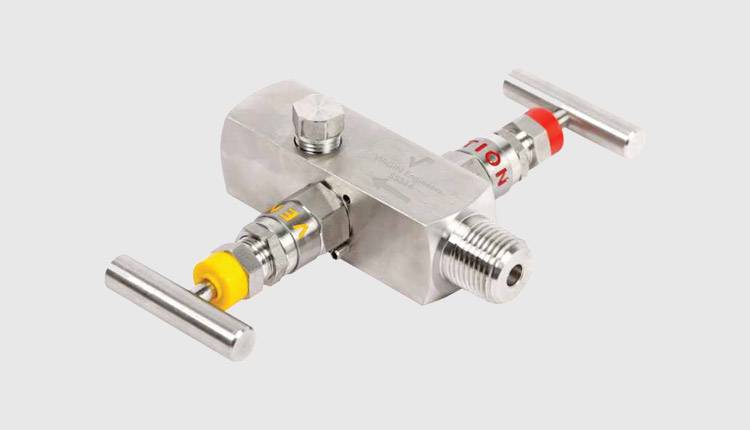

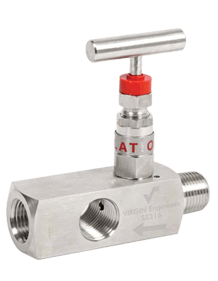

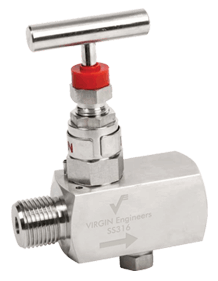

Inconel 625 Needle & Gauge Valves

Inconel® Alloy 600 Needle & Gauge Valve Suppliers, UNS N06625 Needle & Gauge Valve, Grade 600 Inconel Gauge Valves, Inconel 600 Gauge Bleed Needle Valves, DIN 2.4856 Needle & Gauge Valve, Alloy 600 Inconel Industrial Needle & Gauge Valve Manufacturers in Mumbai, India.

Inconel 625 Needle & Gauge Valves are the standard engineering component that founds its utility in numerous industrial applications. These are normally a solitary shutoff needle valve that separates the gauge from the practices. Owning with the great features such as robust design, high-end finish and superior durability these alloy of needles and gauges become the highly demanding product in the market. These come in various exclusive range, shape, size, length, thickness, and specifications in the market at quite a reasonable rate. Therefore the customer can avail this product as per its mention demands and requirements.

Inconel 625 Needle & Gauge Valves are composed of nickel and chromium content adding up with molybdenum and niobium content. The inclusion of niobium content along with the molybdenum content strengthens the alloy’s matrix. These gauge valves generally used in those applications that involve cryogenic temperatures. However, these are offered insusceptibility to aqueous corrosion at elevated temperatures. Moreover, these ensure high tensile strength and toughness at a temperature range of 1093 degree C. In addition to these gauge, valves show good resistance to the crevice, pitting and intercrystalline corrosion. These are greatly immune to chloride ion stress corrosion cracking due to the presence of nickel content.

The gauge valves hot worked or forged in the temperature range 1800-2150 degree F. Therefore these are ideal to control grain size and at the lower end of the temperature range, the finish hot working operation is performed. Due to its good ductility, the alloy is readily designed through the cold working process.

Inconel 625 Screwed End Needle Valve, Inconel 625 Parker Needle Valve, Inconel 625 Hydraulic Needle Valve, Inconel® 625 Multiport Gauge Valves Exporters, Inconel Alloy 625 Gauge Vent Valve Supplier in Mumbai, India.

Inconel 625 Autoclave Needle Valve Needle and Gauge Valves, Inconel 625 Needle / Gauge Valves, Inconel® Alloy 625 Integral Bonnet Needle Valve, Inconel Alloy 625 Gauge Valve, Inconel 625 Forged Body Gauge Valve, Inconel 625 Needle Valve.

Virgin Engineers is one of the recognized and highly acclaimed entities that offer Inconel 625 Needle & Gauge Valves in an exclusive range and types all over the world. As a well-being firm, we are fully immersed in manufacturing, supplying and exporting product worldwide. For its manufacturing process, we utilize the ultimate quality of raw material sourced from the reputed merchants of the market. Therefore to design a perfect dimensional product in our manufacturing plant we have to install the highly advanced tools and machinery. On the other hand, we are employed with the committed employees and qualified professional that is engrossed in obtaining a qualitative range of product.

We take utmost care and attention towards the customer’s requirements and desires, therefore to fulfill their requirements and demands we offer them our product in various customized shapes, sizes and dimensions. In accordance with the norms and regulations of the industry, our whole manufacturing process is been executed and performed.

Testing & quality checking

Being a quality conscious entity we take the greatest care toward the quality of the product, in order to bring out quality assurance product we carefully test and inspect each material of our unit. These tests are like burst test, cryogenic test, pneumatic test, leakage test, intergranular corrosion test, hydrostatic test. Other more tests are a radiographic test, pitting resistance test, shell leakage test, functional test, ultrasonic test, and hardness test.

Packaging of product

To maintain the quality of the product at the time of shipping the product get suitably packed in wooden crates, carton boxes and in pallets.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design :

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | NiCr22Mo9Nb | NCF 625 | NA 21 | ХН75МБТЮ | - |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | 1.00 max | 5.0 max | 58.0 min | 20.0 - 23.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000, MPa – 930 | Psi – 75,000, MPa – 517 | 42.5 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Inconel N06625 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Inconel 625 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

inconel 625 hydraulic needle valve, inconel alloy 625 needle shutoff and regulating valves standards, multiport gauge valves inconel alloy grade 625, inconel 625 screwed end needle valve stockists, inconel® 625 bonnet needle valves size, inconel® alloy 625 gauge bleed needle valves, inconel alloy 625 gauge/needle valve traders, inconel 625 block & bleed gauge valves, inconel 625 needle & gauge valve standards, inconel 625 gauge valve, inconel 625 gauge & needle valve stockholder, inconel® 625 parker needle valve india, buy high quality inconel® 625 needle and gauge valve, needle & gauge valve inconel 625 distributors, 625 inconel alloy gauge valve, inconel alloy 625 high pressure gauge valve size, inconel 625 3 way needle valve dealers, inconel 625 integral bonnet needle valve price, inconel 625 gauge vent valves, inconel alloy 625 autoclave needle valve manufacturer in mumbai, alloy 625 forged body gauge valve types.

© Copyright | Virgin Engineers 2021. All Right Reserved.