- Home

- Products

- Valves

- Manifold Valves

- SS 304H Manifold Valves

SS 304H Manifold Valves

SS 304H 5 Way Manifold Valves Suppliers, Stainless Steel 304H Manifold Valves, SS 304H 2 Way Manifold Valve, DIN 1.4301 Manifold Valve, SS 304H Valve Manifold, Stainless Steel 304H 3 Way Manifold Valves, UNS S30409 Manifold Valves, Grade 304H Stainless Steel Instrument Manifold Valves Manufacturers in Mumbai, India.

When it comes to stainless steel 304H manifold valves, Virgin Engineers is a reputable name in the industry. As a seasoned SS 304H manifold valve manufacturer and supplier based in Mumbai, India, we cater to customers looking for durability, high-temperature resistance, and dependable valve solutions in instrumentation and control systems. Our range includes a wide variety of 304H stainless steel manifold valves, available in 2-way, 3-way, and 5-way configurations, as well as gauge manifolds, remote mount options, and block-and-bleed assemblies. We design our products to ensure secure shutoff, efficient pressure balancing, and reliable isolation in systems that prioritize thermal and pressure stability.

SS 304H 2 Valve Manifold, SUS 304H Manifold Valves, Stainless Steel 304H 5 Valve Manifold, SS 304H 3 Valve Manifold, SS 304H Valves Manifolds Exporters, Stainless Steel 304H Direct-Mount Manifolds, SS 304H Remote-Mount Manifold Supplier in Mumbai, India.

SS 304H V, VB, and VL series Manifolds, SS 304H H Series Manifold Valves, SS 304H R - Type Manifold Valve, SS 304H Instrumentation Manifold Valves, SS 304H Remote-Mount, SS 304H Bellows Sealed Manifolds, AISI 304H Three Way T- Type Manifold Valves, Stainless Steel 304H Double Block Bleed Valves, SS 304H Block and Bleed Valves, SS 304H Hydraulic Manifold.

We produce our 304H SS manifold valves from high-carbon austenitic stainless steel, ensuring compliance with ASTM A182 F304H and ASME B16.34 standards. Renowned for their durability under high temperatures, 304H grade stainless steel manifold valves are perfectly suited for high-pressure steam systems and thermally demanding settings. We design these stainless steel valves to withstand working pressures up to 6000 PSI (414 bar) and temperatures from -54°C to 232°C. We provide various end connection choices, including NPT threads (ASME B1.20.1), BSP parallel threads (ISO 228), and flange ends (ASME B16.5). Standard dimensions vary from ¼” to 1”, and we also offer custom sizing to accommodate specific system designs.

Oil refining, chemical manufacturing, power plants, gas distribution, marine installations, and water treatment sectors extensively use our 304H stainless steel manifold valves. For added versatility, we provide features such as PTFE or graphite-based stem packing, anti-tamper handles, and stem tip variations including needle, ball, and regulating designs. Each 304H steel manifold valve is carefully tested to meet strict quality standards for pressure and leaks, ensuring it works safely and lasts a long time in the field. Every shipment includes full documentation, such as EN 10204 3.1 mill test certificates, dimensional inspection reports, and traceability documents.

We carefully pack all our stainless steel 304H manifold valves using moisture-proof materials and export-grade wooden boxes to ensure they arrive in perfect condition. With a ready inventory on hand, we are equipped to handle urgent and bulk orders efficiently, supplying across India and exporting to the Middle East, Southeast Asia, and Europe. Virgin Engineers is proud to be a reliable source for SS 304H manifold valves, offering robust performance, transparent service, and dependable technical support. For quotes, specifications, or guidance on product selection, we welcome you to get in touch.

Specification

ASTM

ASTM A276, A351, A494 / ASME SA276, SA351, SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | WERKSTOFF NR. | UNS |

| SS 304H | 1.4301 | S30409 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 18 – 20 | - | 8 – 10.5 | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Products

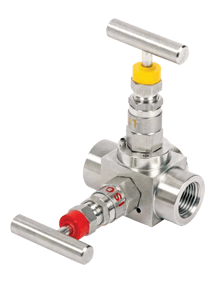

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

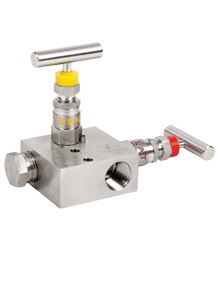

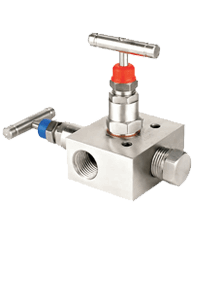

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

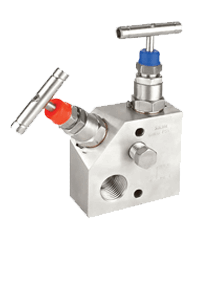

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Stainless Steel S30409 manifold valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on stainless steel 304H manifold valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing , etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

stainless steel 304h 5 valve remote mounted, stainless steel 304h manifold valves manufacturer in mumbai, ss 304h 2 way manifold valve for pressure gauge, ss 304h manifold valves manufacturers in india, ss 304h manifold valves stockholder, stainless steel 304h manifold 3 valves 2 ways, stainless steel 304h 3 way manifold price list, ss 304h manifold valves traders, ss 304h manifold valve size, grade 304h stainless steel manifold valve application, stainless steel 304h 3 valve direct mounted, ss 304h manifold valves stockists, ss 304h manifold mounted ball valves, stainless steel 304h manifold hydraulic valves, stainless steel 304h manifold valves types, buy high quality stainless steel 304h manifold valves, stainless steel 304h manifold valve dealers, ss 304h manifold valves price, ss 304h 2 valve t type manifold valve, grade 304h stainless steel types of manifold valves, stainless steel 304h manifold valves distributors.

© Copyright | Virgin Engineers 2021. All Right Reserved.