- Home

- Products

- Valves

- Manifold Valves

- SS 316L Manifold Valves

SS 316L Manifold Valves

Stainless Steel 316L Manifold Valves Suppliers, SS 316L 2 Way Manifold Valve, Grade 316L Stainless Steel Instrument Manifold Valves, UNS S31603 Manifold Valves, SS 316L Valve Manifold, SS 316L 5 Way Manifold Valves, DIN 1.4404 / 1.4435 Manifold Valve, Stainless Steel 316L Way Manifold Valve Manufacturers in Mumbai, India.

Virgin Engineers is a trusted stainless steel 316L manifold valve manufacturer and supplier in Mumbai, India. We provide expertly crafted solutions for intricate fluid control systems. Our SS 316L manifold valves are crafted for enduring performance and dependability, making them ideal for applications that emphasize corrosion resistance, durability, and secure shut-off. We supply various configurations, such as 2-way, 3-way, and 5-way 316L SS manifold valves, along with gauge, remote mount, and block and bleed options.

Stainless Steel 316L 5 Valve Manifold, SS 316L Remote-Mount Manifold, SS 316L 2 Valve Manifold, Stainless Steel 316L Direct-Mount Manifolds Exporters, SUS 316L Manifold Valves, SS 316L 3 Valve Manifold, SS 316L Valves Manifolds, Supplier in Mumbai, India.

SS 316L V / VB and VL series Manifolds, SS 316L Instrumentation Manifold Valves, SS 316L H Series Manifold Valves, AISI 316L Three Way T- Type Manifold Valves, SS 316L Hydraulic Manifold, SS 316L Block and Bleed Valves, SS 316L R - Type Manifold Valve, SS 316L Remote-Mount, SS 316L Bellows Sealed Manifolds, Stainless Steel 316L Double Block Bleed Valve.

Each 316L stainless steel valve manifold is made from low-carbon austenitic stainless steel that meets ASTM A182 F316L standards and follows ASME B16.34 design rules. These valves can handle working pressures up to 6000 PSI (414 bar) and work well in temperatures ranging from -54°C to 232°C. We have standard sizes like ¼”, ½”, ¾”, and 1”, with end connections available in NPT, BSP, and flanged styles to fit different systems. If your project needs custom options, we can create specific SS 316L valve assemblies to meet your requirements.

Industries such as chemical processing, oil and gas, pharmaceuticals, water treatment, and power generation commonly use our 316L grade stainless steel manifold valves. These products include features such as PTFE or graphite packing, tamper-proof handles, and various tip options for accurate control. Every valve undergoes testing with water and air in compliance with API 598 and MSS SP-99 standards. Alongside performance, we offer comprehensive documentation, which includes EN 10204 3.1 mill test certificates, inspection reports, and size checks to ensure complete traceability.

At Virgin Engineers, we ensure that all 316L steel manifold valves are packed securely with moisture-resistant materials and sturdy wooden crates to safeguard against any damage during transit. We maintain a prepared inventory to assist with urgent and large orders throughout India, the Middle East, Southeast Asia, and Europe. If you need a reliable 316L manifold valve supplier in India or require expert advice on specifications, our team is ready to assist you. Contact us for assistance with technical difficulties, pricing inquiries, or to obtain a personalized quote today.

Specification

ASTM

ASTM A276, A351, A494 / ASME SA276, SA351, SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

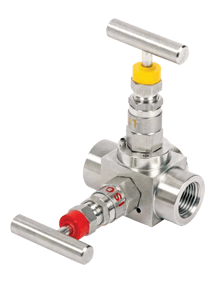

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

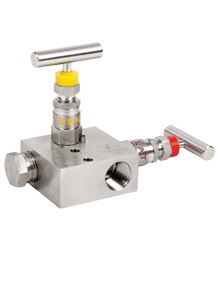

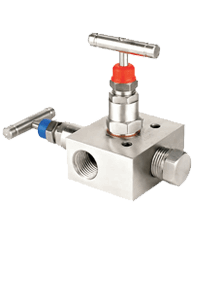

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

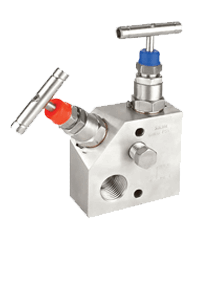

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Stainless Steel S31603 manifold valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on stainless steel 316L manifold valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

ss 316l manifold valves stockholder, stainless steel 316l way manifold price list, stainless steel 316l manifold valves distributors, stainless steel 316l 5 valve remote mounted, ss 316l manifold valves traders, ss 316l 2 way manifold valve for pressure gauge, stainless steel 316l manifold valves manufacturer in mumbai, ss 316l manifold valve size, ss 316l manifold valves stockists, buy high quality stainless steel 316l manifold valves, grade 316l stainless steel types of manifold valves, grade 316l stainless steel manifold valve application, stainless steel 316l manifold hydraulic valves, stainless steel 316l manifold valves types, steel 316l manifold valve dealers, ss 316l manifold mounted ball valves, ss 316l manifold valves manufacturers in india, ss 316l manifold valves price, stainless steel 316l manifold 3 valves 2 ways, ss 316l 2 valve t type manifold valve, stainless steel 316l 3 valve direct mounted.

© Copyright | Virgin Engineers 2021. All Right Reserved.