- Home

- Products

- Valves

- Manifold Valves

- Stainless Steel 321/321H Manifold Valves

SS 321/321H Manifold Valves

Stainless Steel 321H Way Manifold Valves, Stainless Steel 321H Manifold Valves, DIN 1.4541/1.4878 Manifold Valve, SS 321 2 Way Manifold Valve, SS 321/321H Valve Manifold , SS 321 5 Way Manifold Valves Suppliers, Grade 321 / 321H Stainless Steel Instrument Manifold Valves, UNS S32100 / S32109 Manifold Valves Manufacturers in Mumbai, India.

Virgin Engineers is a trusted stainless steel 321 and 321H manifold valves manufacturer and supplier in Mumbai, India. These valves are specifically crafted for high-temperature applications and outstanding mechanical durability. Our SS 321 valve manifolds are perfect for instrumentation and control systems functioning in challenging thermal conditions. We provide a range of options, including 2-way, 3-way, and 5-way configurations, featuring block and bleed as well as gauge manifold valves for versatile installation.

Each 321 stainless steel manifold valve is manufactured using titanium-stabilized austenitic stainless steel, conforming to ASTM A182 F321 and F321H specifications. The 321 grade offers superior resistance to intergranular corrosion after welding. On the other hand, our stainless steel 321H manifold valves are made with a higher carbon content, giving them better strength at elevated temperatures. These valves support working pressures up to 6000 PSI and can handle temperatures up to 816°C, depending on the system design.

SS 321 V / VB and VL series Manifolds, SS 321/321H Remote-Mount Manifold, SUS 321 Manifold Valves, Stainless Steel 321H Direct-Mount Manifolds, Stainless Steel 321 5 Valve Manifold Exporters , SS 321H 2 Valve Manifold, SS 3213 Valve Manifold, SS 321H Valves Manifolds Supplier in Mumbai, India.

SS 321/321H Block and Bleed Valves, Stainless Steel 321 Double Block Bleed Valve, SS 321H R - Type Manifold Valve, SS 321 Hydraulic Manifold, SS 321H Bellows Sealed Manifolds, SS 321 Instrumentation Manifold Valves, AISI 321H Three Way T- Type Manifold Valves, SS 321 Remote-Mount.

We offer SS 321 instrumentation valves in standard sizes ranging from ¼” to 1”, featuring NPT, BSPT, and flanged end connections. All 321H stainless steel manifold valves come with dependable stem packing, available in either PTFE or graphite, and we provide choices for ball, needle, or regulating stem tips. From offshore rigs to petrochemical plants and power stations, our valve manifolds made from 321H grade stainless steel stand out as a reliable option for essential flow control.

Virgin Engineers ensures that every 321 and 321H manifold valve undergoes pressure testing in accordance with API 598 or MSS SP-99 standards. EN 10204 3.1 mill test certificates and comprehensive dimensions data are included with each purchase. We utilize solid wooden boxes and moisture-resistant material to transport valves. Our experts can give technical data, stock status, and competitive prices for Indian SS 321H manifold valves.

Specification

ASTM

ASTM A276, A351, A494 / ASME SA276, SA351, SA494

Pressure rating

up to 6000 psig @ 100° F (414 barg @ 38° C).

Size Range

1/8 to 1”, Custom Sizes available on request

Temperature

up to 1200°F(648 °C)

Connections

Thread, Weld or Tube End

Standard

DIN, ASTM, BS and all International Standards.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | - | - | - | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | - | - | - | X12CrNiTi18-9 |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) – 0.70 max |

| SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 4(C+N) – 0.70 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F)) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

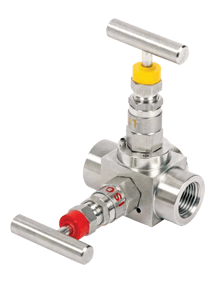

2 – Way Manifold Valve

Manifold-R-2 Way-01

Manifold-R-2 Way-02

Manifold-R-2 Way-03

Manifold-R-2 Way-04

Manifold-R-2 Way-05

Manifold-R-2 Way-06

Manifold-T-2 Way

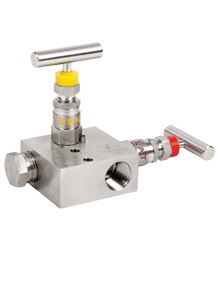

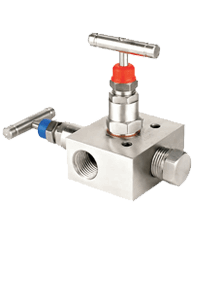

3–Way Manifold Valve

Manifold-R-3 Way-01

Manifold-R-3 Way-02

Manifold-R-3 Way

Manifold-H-3 Way

Manifold-H-3 Way

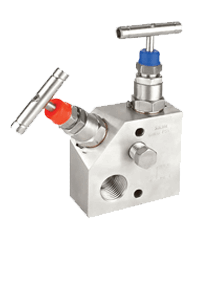

5–Way Manifold Valve

Manifold-R-5 Way-01

Manifold-R-5 Way-02

Manifold-R-5 Way-03

Quality Assurance

Stainless Steel S32100, S32109 manifold valves are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on stainless steel 321/321H manifold valves are burst tests, Ultrasonic Test, Mechanical Testing, Cryogenic testing, low temperature testing, High pressure gas testing, High temperature testing , etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

321 stainless steel manifold valves types, 321 stainless steel manifold valve dealers, buy high quality stainless steel 321H manifold valves, stainless steel 321 manifold valves manufacturer in mumbai, stainless steel 321 manifold 3 valves 2 ways, ss 321 2 way manifold valve for pressure gauge, ss 321H manifold valves traders, stainless steel 321H 5 valve remote mounted, ss 321 manifold valves manufacturers in india, grade 321 stainless steel types of manifold valves , ss 321/321H 2 valve t type manifold valve, stainless steel 321/321H manifold valves distributors, stainless steel 321 manifold hydraulic valves, ss 321H manifold mounted ball valves, ss 321H manifold valves price, ss 321H manifold valves stockists, stainless steel 321H way manifold price list, grade 321 stainless steel manifold valve application, stainless steel 321H 3 valve direct mounted, ss 321H manifold valve size, ss 321 manifold valves stockholder.

© Copyright | Virgin Engineers 2021. All Right Reserved.