- Home

- Products

- Needle & Gauge Valves

- Stainless Steel 347 / 347H Needle & Gauge Valves

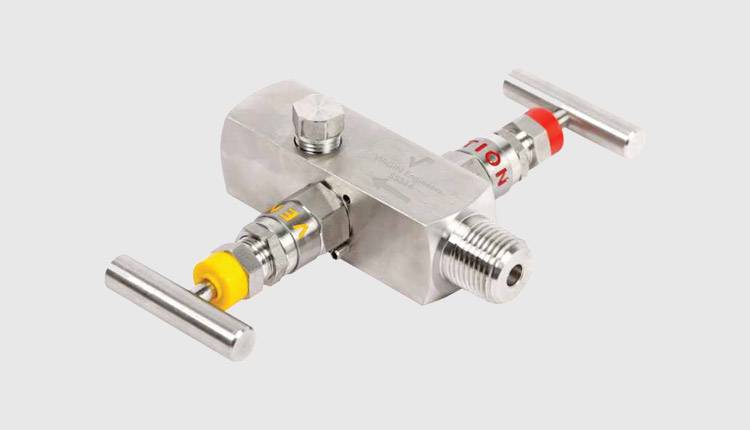

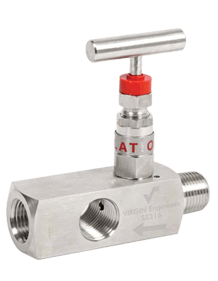

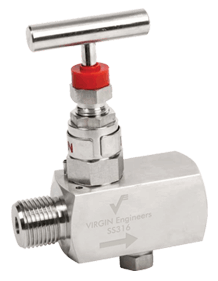

SS 347 / 347H Needle & Gauge Valves

SS 347 Gauge Bleed Needle Valves Suppliers, SS 347H Needle and Gauge Valves, Stainless Steel 347 Needle / Gauge Valves, SS Gr.347/347H Industrial Needle & Gauge Valve, Grade 347 Stainless Steel Gauge Valves, SS 347H Needle & Gauge Valves Manufacturers in Mumbai, India.

Virgin Engineers is a renowned and authorized organization fully engaged in manufacturing, exporting and supplying Stainless Steel 347 / 347H Needle & Gauge Valves. We designed the product in compliance with national and international standards by using high-quality raw material. While the raw material comes in our manufacturing unit we thoroughly examined the entire raw material under the supervision of quality controllers.

By using high tech machinery and latest tools we manufacture the product as per the norms and standards of the industry. We cater our product to both national as well as international clients. We are a customer oriented firm that aims to offer high quality of standard product to our esteem patrons. As per their given order or demand, we facilitate our product in varied shapes, design, grade, size, length, and thickness. On the other hand, to provide maximum satisfaction we offer the best services and product at demanded by the customers.

SUS 347H Parker Needle Valve, 347H Stainless Steel Multiport Gauge Valves, Grade 347 SS Screwed End Needle Valve, SS 347 Gauge Vent Valves Exporters, Stainless Steel 347H Hydraulic Needle Valve Supplier in Mumbai, India.

SS 347H Integral Bonnet Needle Valve, SS 347H Forged Body Gauge Valve, Austenitic Stainless Steel 347 Needle / Gauge Valves, AISI 347 Needle and Gauge Valves, SS 347H Needle Valve, SS 347 Autoclave Needle Valve, SS 347/347H Gauge Valve

Details about product

Stainless Steel 347 / 347H Needle & Gauge Valves is the type of components that are formed with high alloy austenitic stainless steel containing chromium, columbium and tantalum content. The presence of chromium and tantalum content offers superior creep and stress rupture properties. These austenitic stainless steel needles & gauge valves offer superior general corrosion resistance and in oxidizing circumstances somewhat it offers good resistance other than other grades. The presence of tantalum and columbium features exceptional resistance to corrosion resistance. These gauge valves offer good creep strength and oxidation resistance up to 816 degree C and also exhibits good low-temperature toughness.

The high carbon present in the alloy enhances excellent higher strength and creep resistance above 537 degrees C. These alloys of needles & valves gauges are mainly used in the chromium carbide precipitation circumstances. These needle & gauge valves are only get hardened through the cold working process, therefore these ensures superior ductility and are easily formed. On the other hand, these are readily welded by means of standard welding process that facilitates good weldability.

Testing & quality checking

We implement various testing and inspection programs at our manufacturing plant to acquire an accurate and durable quality product. These tests are like a hydrostatic test, cryogenic test, burst test, intergranular test, radiographic testing, and pitting resistance test. Further other test is a leakage test, shell leakage test, ultrasonic test, pneumatic test, and functional test.

Test certificate

To prove that the products offered by us are designed from superior quality of material we offer material test certificates to our customers in accordance to EN10204/3.1 B. These certificates are like raw material certificate, 100% radiography test certificates, and third-party inspection reports.

Documentation

In order to give complete details of the product, the various important documentations are attested with the product and are given to the customers. This documentation is like fumigation certificate, guarantee letter, heat treatment charts, NABL approved lab test report, , and commercial invoice.

Packaging of product

The products are supplied in wooden cartons, wooden pallets, wooden boxes, wooden crates, and in cases that assurer’s prevention from rust and damage during the transit.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design:

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | 08Ch18N12B | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | - | X6CrNiNb18-12 |

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 20.00 | 10xC – 1.10 | 9.00 - 13.00 | 62.74 min |

| SS 347H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 8xC – 1.10 | 9.0 -13.0 | 63.72 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Stainless Steel S34700/S34709 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on SS 347/347H Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

stainless steel 347h autoclave needle valve manufacturer in mumbai, ss 347 gauge bleed needle valves, stainless steel 347/347h hydraulic needle valve, ss 347 block & bleed gauge valves, ss 347h gauge/needle valve traders, ss 347h gauge & needle valve stockholder, stainless steel 347h forged body gauge valve types, stainless steel 347/347h needle & gauge valve standards, ss 347 screwed end needle valve stockists, buy high quality austenitic stainless steel 347 needle and gauge valve, stainless steel 347h gauge valve, 347 ss high pressure gauge valve size, ss 347 parker needle valve india, stainless steel multiport gauge valves grade 347h, ss 347 needle valve standards, stainless steel 347h 3 way needle valve dealers, ss 347h integral bonnet needle valve price, ss 347h bonnet needle valves size, stainless steel 347h needle valve distributors, 347 ss gauge valve, stainless steel 347h gauge vent valves.

© Copyright | Virgin Engineers 2021. All Right Reserved.