- Home

- Products

- Needle & Gauge Valves

- SS 304 Needle & Gauge Valves

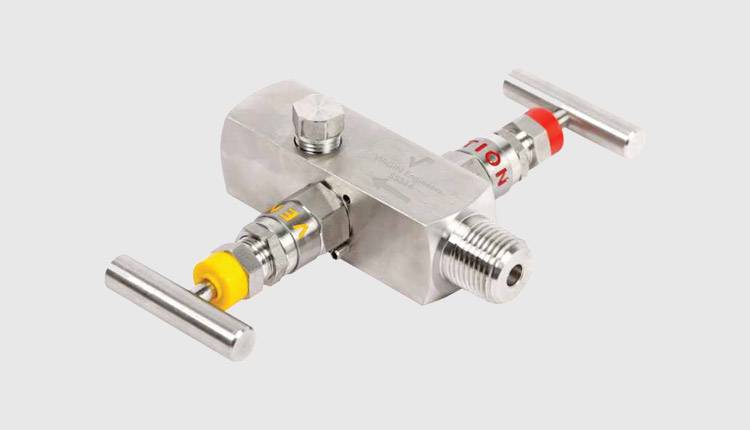

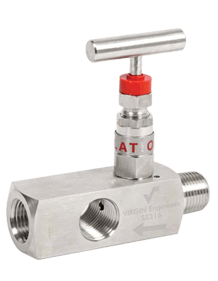

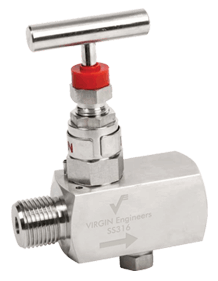

SS 304 Needle & Gauge Valves

Stainless Steel 304 Needle & Gauge Valves, SS 304 Needle & Gauge Valves, Grade 304 Stainless Steel Gauge Valves, SS Gr.304 Industrial Needle & Gauge Valve, SS 304 Gauge Bleed Needle Valves Suppliers, SS 304 Needle and Gauge Valves Manufacturers in Mumbai, India.

Virgin Engineers is one of the recognized and trustworthy endeavors that affianced in the field of manufacturing, supplying and trading a wide range of Stainless Steel 304 Needle & Gauge Valves. The product range we are supplying is achieved from the certified and foremost vendors that fabricate the product as per the national and international standards. Additionally only top-notch quality raw material is utilized by us for its fabrication process, however, our manufacturing process is operated with ultra-modern machines and latest technology so as to meet up durable quality and finish end product.

Owning with the support of dedicated employees and experts we are able to offer our quality range product in various specifications, length, size, grade and dimensions according to the demands and requisites mention by the clients. In addition, we strive to give complete satisfaction to them thus we facilitate them the best quality product as per the demand made by them. Furthermore, we assure to provide the product, without any defect and consisting good features.

Stainless Steel 304 Hydraulic Needle Valve, SS 304 Gauge Vent Valves Exporters, Grade 304 SS Screwed End Needle Valve, SUS 304 Parker Needle Valve, 304 Stainless Steel Multiport Gauge Valves Supplier in Mumbai, India.

SS 304 Autoclave Needle Valve, SS 304 Needle Valve, SS 304 Gauge Valve, SS 304 Forged Body Gauge Valve, Austenitic Stainless Steel 304 Needle / Gauge Valves, SS 304 Integral Bonnet Needle Valve, AISI 304 Needle and Gauge Valves.

Product description

Stainless Steel 304 Needle & Gauge Valves are formed with the most common form of 304 stainless steel alloy that is a modification of 18/8 austenitic steel alloy containing 18% of chromium, 8% of nickel along with low carbon content. These alloy of needle & gauge valves delivers superior resistant in an extensive range of corrosive media as well as atmospheric environments. These are susceptible to corrosion from chloride solutions. However in warm chloride environment these deliver superior resistance crevice and pitting corrosion.

Furthermore, these resist stress corrosion cracking above about 60 degrees C. The valves also possess good oxidation resistance in intermittent services to 870 degrees C whereas in constant services to 925 degree C. Moreover, it enhances higher tensile strength, hardness, and superior mechanical properties. These ensure superior toughness even down to cryogenic temperatures. Without intermediate annealing, these are greatly deep drawn. In addition to these needles & valves gauge facilitates superb welding characteristics, therefore for welding thin sections post welding annealing is not required.

Before delivering the product to the customers we rigorously check the product on a variety of grounds in order to collect the quality product. These tests are like a mechanical test, chemical analysis, pitting resistance test, hardness test, flattening test, radiography test. Other more tests are an ultrasonic test, flaring test, tensile strength test and macro/micro test.

Test certificates

We attest important test certificates along with the supply that proves the quality of the product. These certificates are like raw material test certificates, 100% radiography test report and third-party inspection reports.

Documentation

At the time of product delivery, the necessary documentation is given along with the product. Such documents are like quality assurance plan, fumigation certificates, specification guide, heat treatment charts, commercial invoice, raw material traceability records and guarantee letters.

Packing of product

To avoid rust and scratches throughout transportation the product gets appropriately packed with waterproof packing material that assures great safety and protection. However, these get packed in plywood cartons, pallets, cases, boxes and in crates.

Specification

Types

Needle Valve, Gauge Valves

Needal Valves Sizes

1/8" TO 2" (3 mm to 50 mm) Max Pressure:pressure -150#, 300#,600#

Needle Valves Design:

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

End Connection Gauge Valves :

½" NPT / G ½ / ½" BSPT

Temperature

-20 to 650°F (-28 to 343°C)

Gauge Valves Maximum working pressure

Up to 6000 psig (413 bar)

Flow Pattern

Straight/ Angle

End Connections Needle Valves :

NPT, tube socket weld, pipe socket weld,

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | - | 8 – 11 | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Products

Needle Valve - F x F

Needle Valve – F x F – HP

Hex Needle Valve – F x F

Hex Needle Valve – M x F

Hex Needle Valve – Vent

Needle Valve – M x M

Gauge Valve – Multiport

Gauge Valve – Vent

Quality Assurance

Stainless Steel S30400 Needle & Gauge Valve are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFF. Our products undergo stringent quality tests before they are dispatched.

Material Testing

The material tests performed on Stainless Steel 304 Needle & Gauge Valve are PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Popular Searches

stainless steel 304 needle & gauge valve standards, ss 304 needle valve standards, stainless steel 304 gauge valve, ss 304 gauge bleed needle valves, stainless steel 304 gauge vent valves, stainless steel multiport gauge valves grade 304, 304 ss high pressure gauge valve size, stainless steel 304 forged body gauge valve types, ss 304 block & bleed gauge valves, ss 304 bonnet needle valves size, stainless steel 304 hydraulic needle valve, ss 304 integral bonnet needle valve price, ss 304 screwed end needle valve stockists, stainless steel 304 3 way needle valve dealers, stainless steel 304 autoclave needle valve manufacturer in mumbai, ss 304 parker needle valve india, stainless steel 304 needle valve distributors, 304 ss gauge valve, ss 304 gauge & needle valve stockholder, buy high quality austenitic stainless steel 304 needle and gauge valve, ss 304 gauge/needle valve traders.

© Copyright | Virgin Engineers 2025. All Right Reserved.